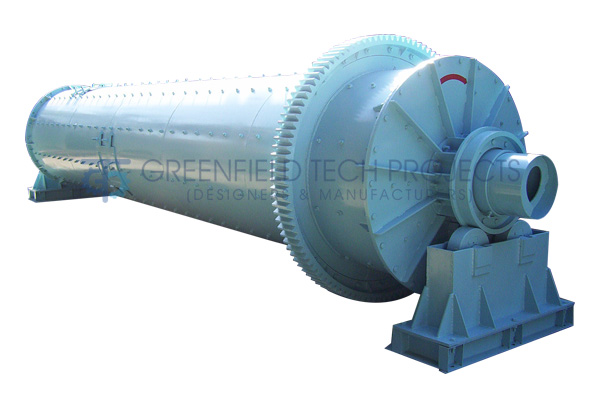

Continuous Ball Mill Manufacturers - We are a leading Continuous Ball Mill Manufacturer in India. Continuous Ball Mill is designed and developed by international quality standards.

Heavy duty, continuous type ball mill is with three compartment and screen. Replaceable Liners are fixed inside entire mill. Liners material and shape is selected based on material to be grind. Input material is fed in two primary grinding compartments. Large diameter balls for reduce particle size are laying inside first compartment. Material comes into second compartment for further grinding. Small size Balls are laying inside second compartment. Material comes into third for fine grinding. Smaller size media are laying inside third compartment for fine grinding. Diaphragms may place to regulate material level and control retention time. Material is feed and discharged through hollow trunnion at opposite end. Accessories like air classifier, cyclone, blower, return air circuit or dust collector can also be placed for close loop system. Two tiers fixed on both end of mill, which are rotate on four rollers. Rollers are fixed on support and oil immersed. Mill rotates on four roller and two tiers. Girth gear is fixed on shell, which driven mating gear, gearbox and motor, which are fixed on heavy drive base.

GREENFIELD Continuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous operation. It is for grinding Ceramics, Cement, Pencil, Paint, Chemical, Ink, Marble, Coal, minerals, Ferro Alloys etc.