Greenfield Tech Projects is one of the leading and reputed manufacturing company in India with 3 decades of experience in the field of drying and processing of Industrial as well as food grade materials. Greenfield Paddle Dryers are designed and manufactured to that efficiency that it can dry all kinds of sludge by utilizing either steam or heating mantles or oil as an heat source.

Working Principle:

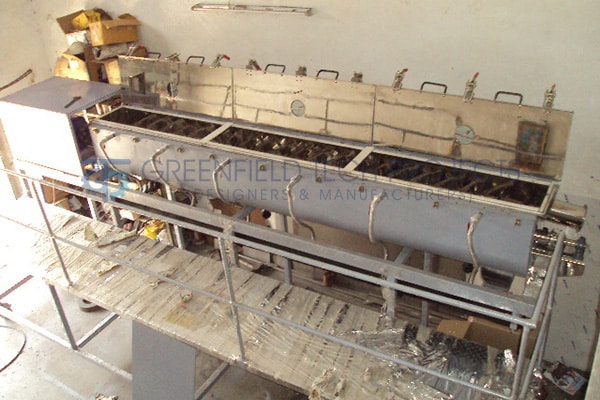

The paddle dryer for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and material transferring paddles, makes high heat transferring efficiency, and provide self-cleaning function. The special rectangular shaped paddles does the mixing, stirring and material transferring with high efficiency and self-cleaning function in the heated trough surface.

Rectangular shaped paddles are concentrated on the hollow shaft. Heat media flow through the trough and heats the chamber uniformly.. The heat transferring area in the effective volume is very high. The temperature range of heating media is 40 °C to 320 °C. All heat is utilized for to drying the material and there is no heat loss. The surface of rectangular shaped paddles has self-cleaning function. The trough of hollow Paddle dryer is U shaped. To avoid any leakage of material, there’re sealed terminal cover and top cover with the trough. The heat transferring media flow through the rotation connector, jacket’s shell and hollow stirring shaft.

Features:

- The heat consumption of paddle Dryer is low

- The cost of the paddle dryer is low;

- The range of material to be processed is wide;

- The pollution is less: Without any carrying air, very few powder is carried out;

- The operation cost is low;

- Steady operation: The material particles fully contact heat transferring surface, because of the special compressing and swell-stirring effect of the paddle. The difference of the temperature, humidity and mixing effect are very small in the different axial area, so to ensure the stability of process.